``IoT for CNC`` refers to the application of Internet of Things (IoT) technology to CNC machines, which enhances business efficiency.

What is IOT for CNC?

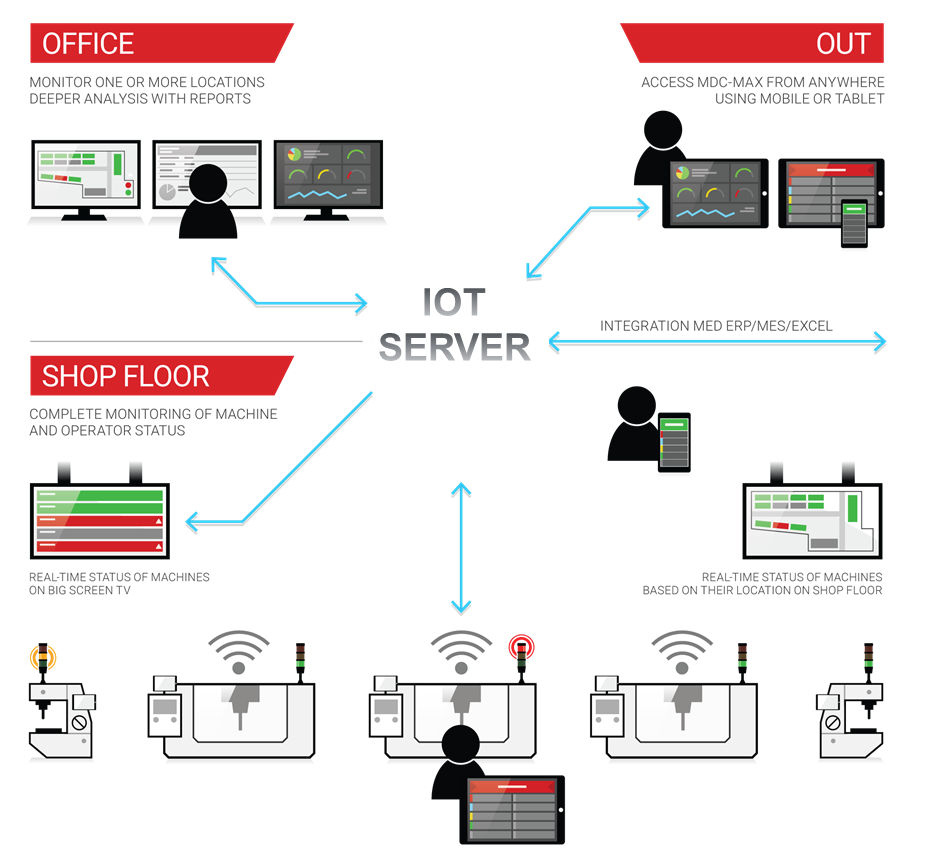

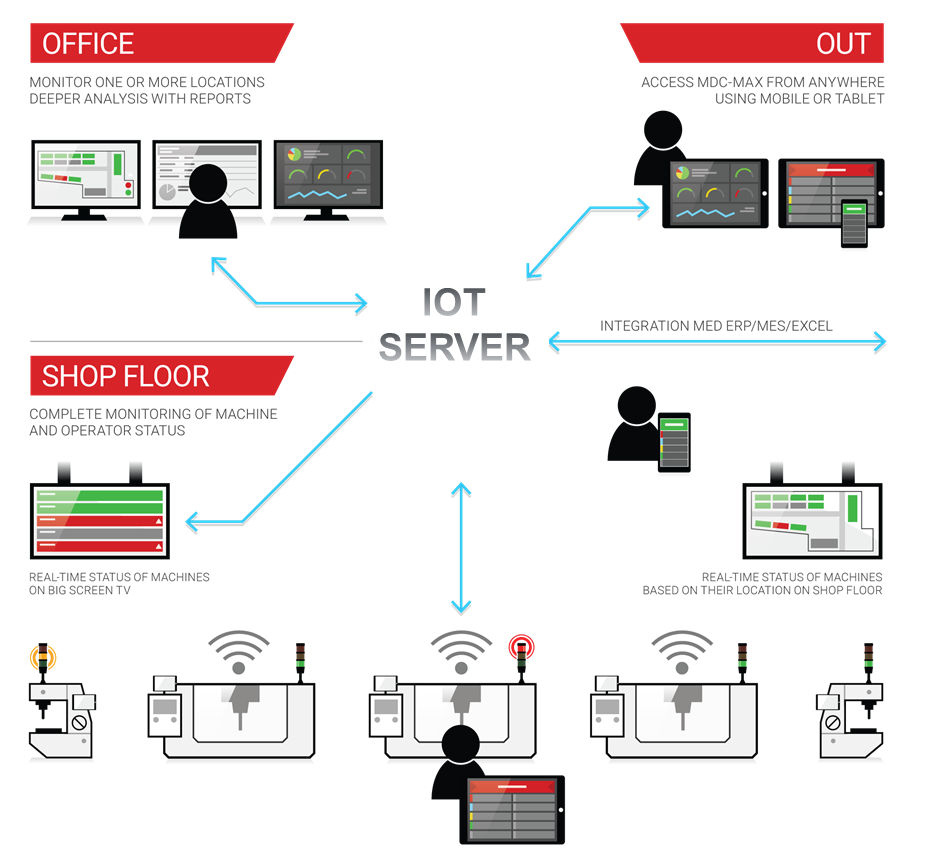

The working principle of the IOT for CNC system

Benefits of implementing IOT for CNC in industrial businesses

- Improved production efficiency: IOT for CNC allows businesses to easily gather real-time data from their machinery and utilize this data to increase production efficiency. It helps reduce machine errors, increase production output, and overall improve efficiency.

- Effective maintenance planning: By monitoring machine data, the IOT system can assist business owners in detecting potential maintenance issues before they escalate into more serious problems. This helps reduce machine failures and lowers maintenance costs compared to traditional methods.

- Remote monitoring and control: One notable advantage of IOT for CNC is the ability to remotely monitor and control machinery. This is particularly beneficial for companies with multiple factory locations or dispersed manufacturing facilities.

- Quality control: By collecting and analyzing data from the machinery, the IOT system can identify quality issues, allowing business owners to improve the overall product quality by making informed adjustments.

- Expedited decision-making: With real-time access to machine data, business owners can make prompt decisions regarding their production processes. This enables quick decision-making and ensures access to accurate information.

The results of implementing IOT for CNC in the business

IOT for CNC, when installed for machine monitoring along with barcode readers for operators to input work stoppage codes, addresses various production issues. Two main issues that are focused on are poor maintenance responsiveness and slow tool change, which hinder the machine from returning to production promptly.

After implementing IOT for CNC, customers have taken multiple measures, including implementing a prioritized maintenance schedule and ensuring tool readiness in advance. Currently, they are able to utilize the machinery as a whole by more than 68% and achieve production targets. This increase in profitability enables them to invest in new factories.